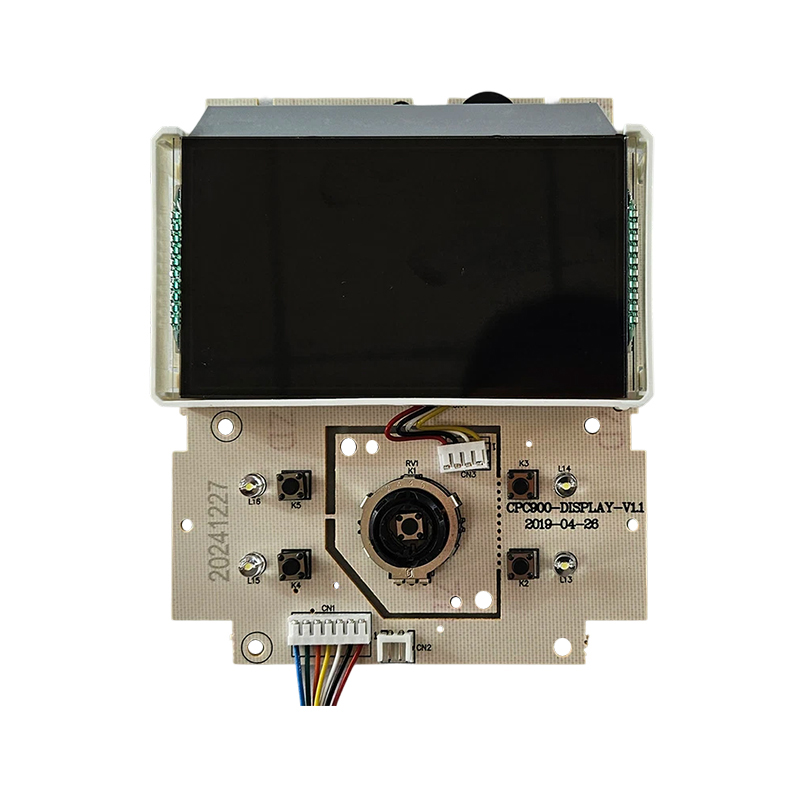

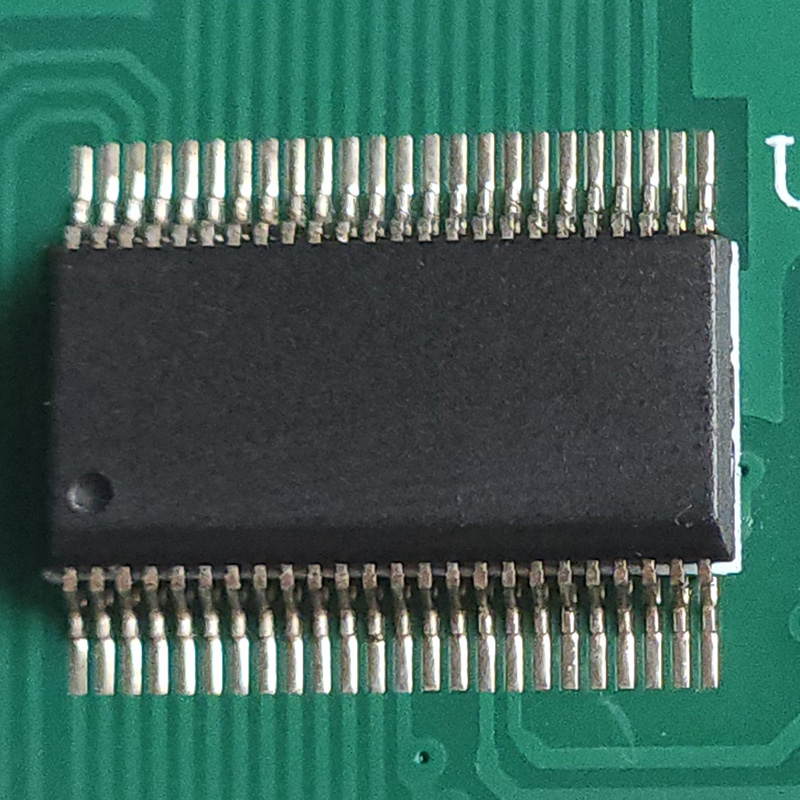

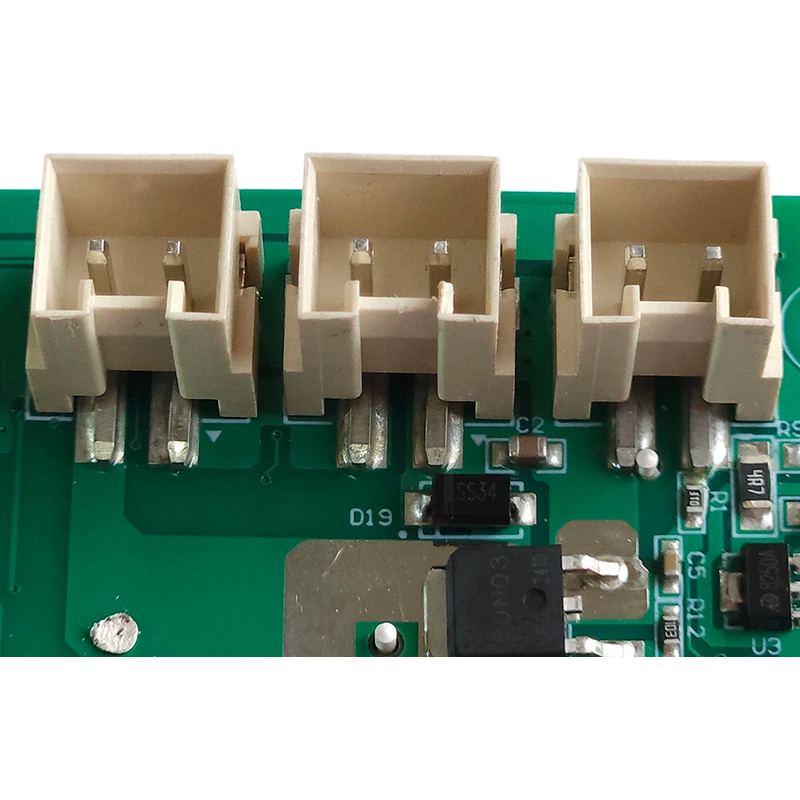

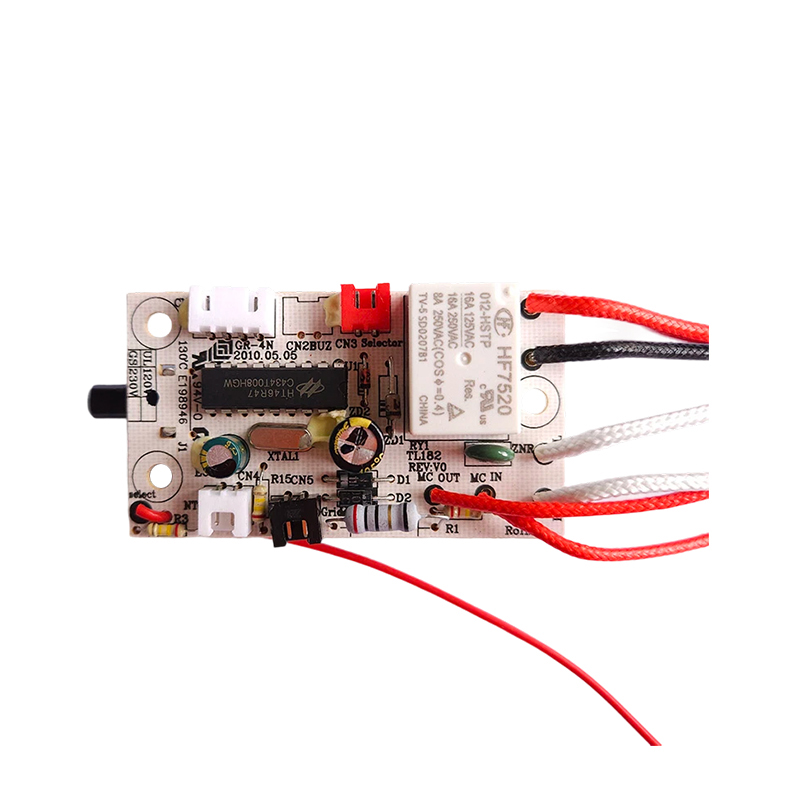

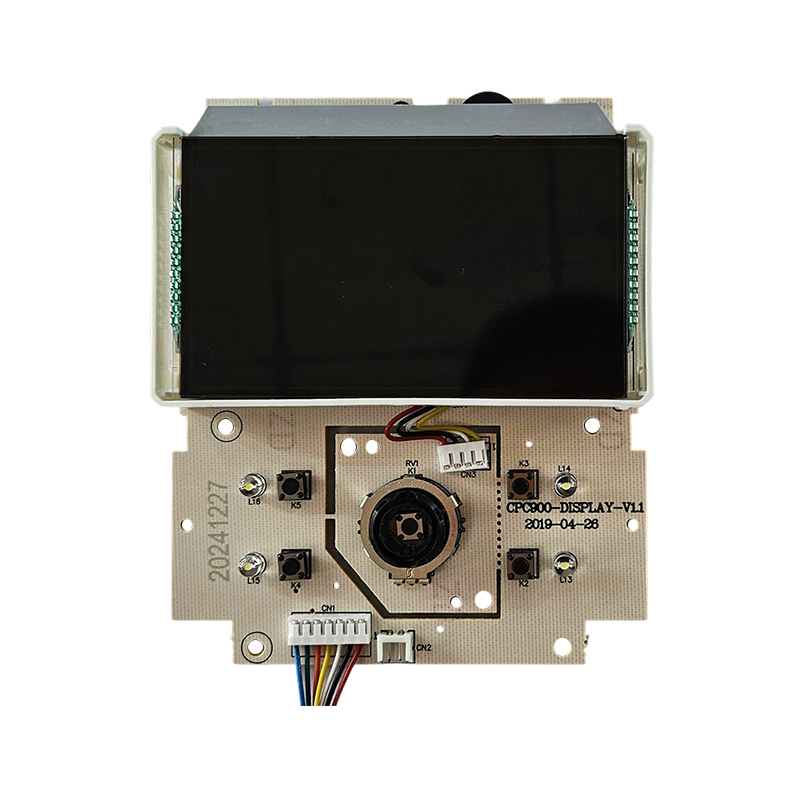

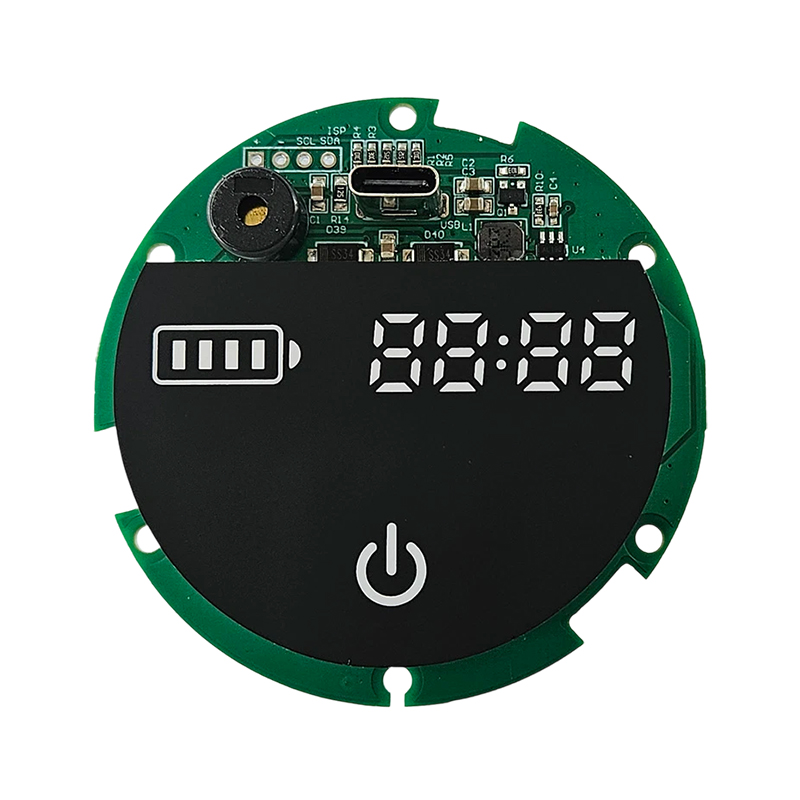

As a representative of modern smart kitchen appliances, the core control capabilities of an electric pressure cooker LCD rely on the highly coordinated integration of its built-in industrial control circuit board and LCD display system.

- +86-15012910684

- wvqcel0103@163.com

- Room 1008, Building 8, Jinhuafa Industrial Park, Longhua Street, Longhua District, Shenzhen