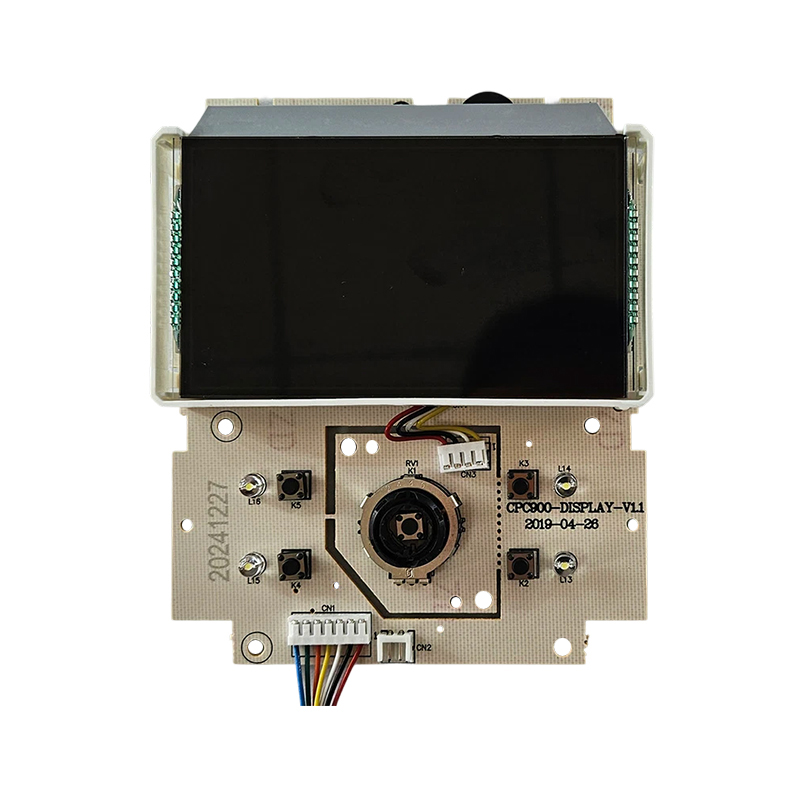

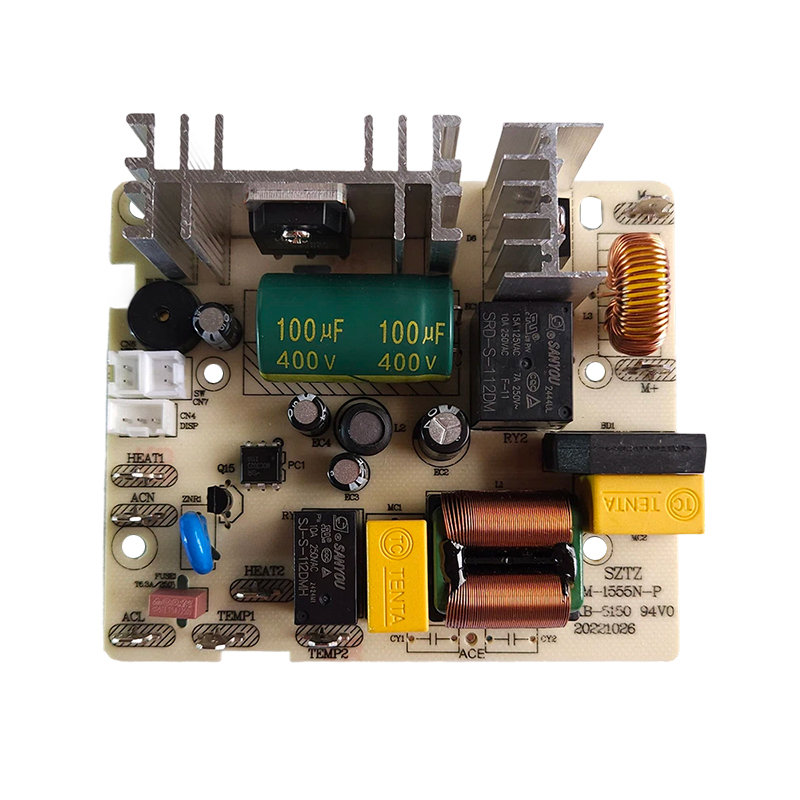

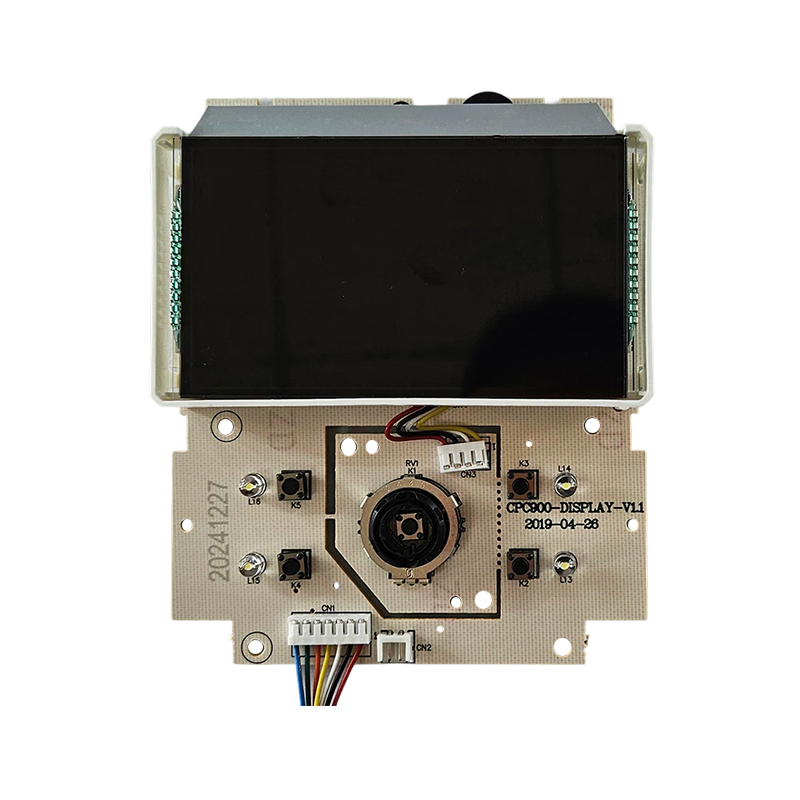

The electric pressure cooker LCD industrial control circuit board can achieve precise control of heat and time. Its core lies in the sophisticated sensor system and data processing mechanism.

- +86-15012910684

- wvqcel0103@163.com

- Room 1008, Building 8, Jinhuafa Industrial Park, Longhua Street, Longhua District, Shenzhen